Design & Development

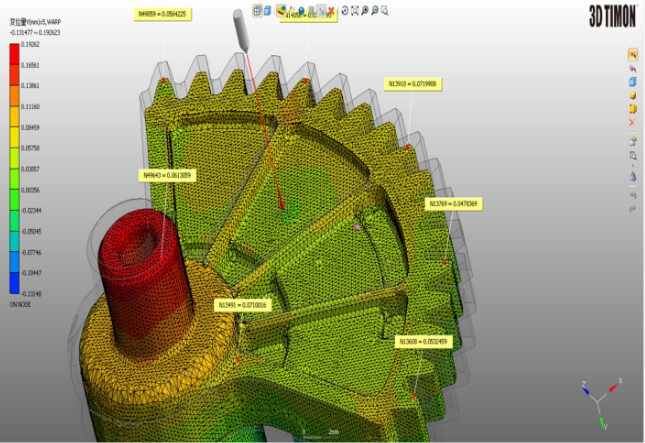

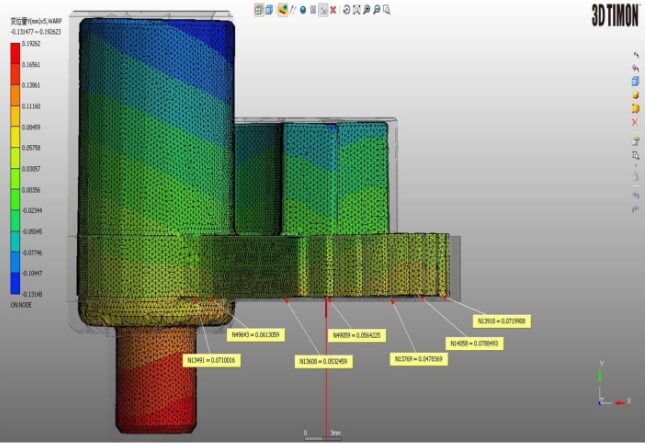

Based on analysis results, we provide support and proposals for product development. Through analysis, we design optimal gate positions and cooling circuits, and work to improve flowability, reduce deformation and warpage, and predict weld and take countermeasures. We work to eliminate problems in advance and achieve stable quality.

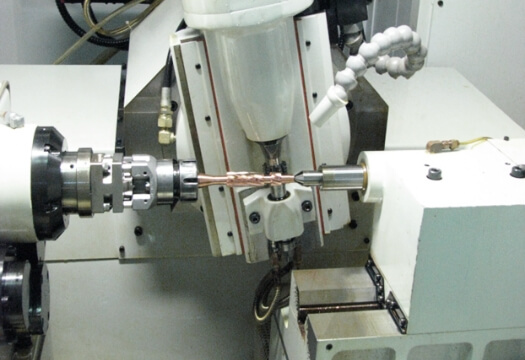

Processing Technology

We provide precision machining of various gears such as worm gears, spiral bevel gears, face gears, and mechanical parts that require high precision in the micron range.

Owned Equipment

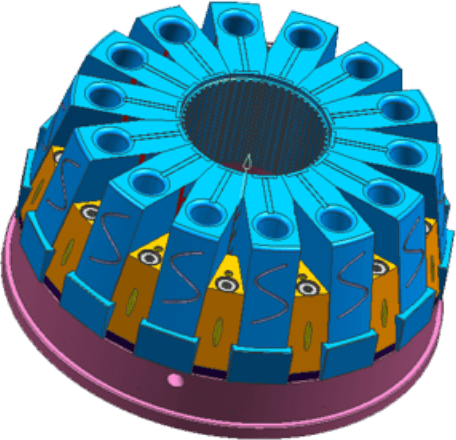

Shenzhen factory is equipped with specialized machines for mold making.

| Maker | Name | Machine Quantity |

|---|---|---|

| Makino | CNC Machining Center | 1 |

| FANUC | 1 | |

| joint | 1 | |

| Hamai | CNC Hobbing Machine | 1 |

| Sodick | NC electrical discharge machine | 5 |

| Sodick | Wire cut | 3 |

| Sodick | Small-hole electrical discharge machine | 1 |

| Mazak | NC Lathe machine | 1 |

| Okamoto | Cylindrical grinding machine | 1 |

| Okamoto/Mitsui | Surface grinder | 4 |

| Shizuoka | NC milling machine | 1 |

| – | Lathe machine | 4 |

| – | General-purpose milling machine | 2 |

| – | Precision drilling machine | 1 |

| – | Laser Welding Machine | 1 |

| HAN’S | Laser Processing Machines | 1 |

Mold Maintenance

During injection molding, gas contamination generated from the molding material adheres to the mold. If left unattended, this contamination can solidify and become difficult to remove, or cause rust and corrosion. Daily maintenance and periodic overhauls are essential to maintain the mold life as per the durability shot and to maintain the quality of the molded product for a long period of time. We manage the number of shots according to the mold structure and molding material, and manage the maintenance cycle independently. This maintains mold durability and molded product quality.