Quality Assurance System

●APQP

Phase management based on Advanced Product Quality Planning

●Design FMEA (Failure Mode Effects Analysis)

- When launching a new mold, Cross Functional Team meetings are held to ensure high productivity in mold making

- Die development using flow analysis

- Standardization of mold design

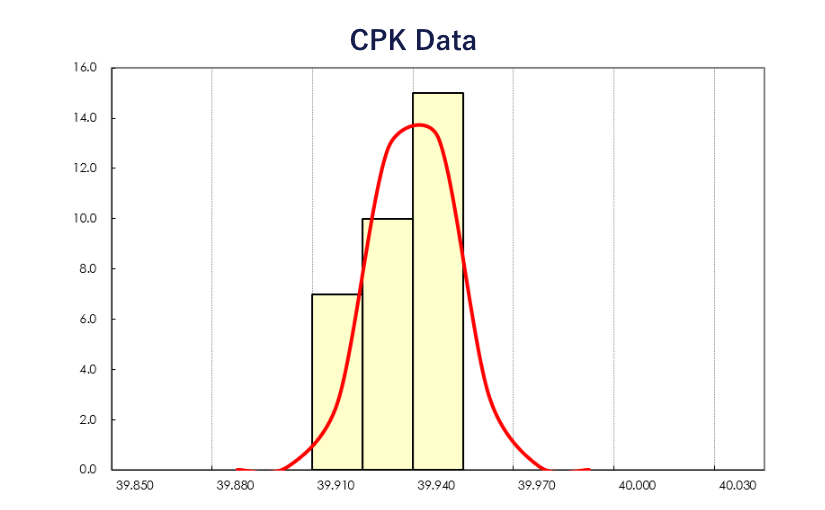

●Initial Flow Control

- Stable quality is achieved by implementing CPK for process capability.

●Ability to solve problems by thoroughly pursuing the causes of defects

- Thorough “why-why analysis” by molding technicians to find the root cause and take countermeasures

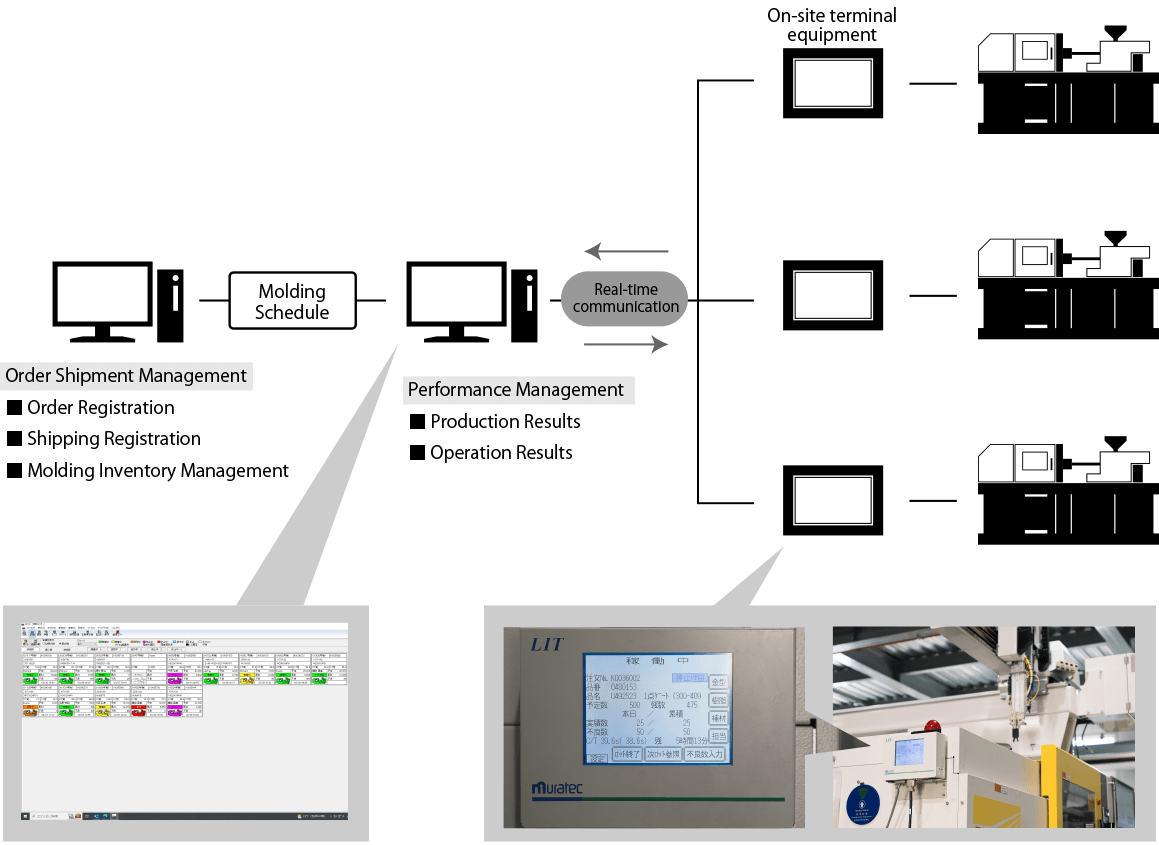

Production Control System

A production control system with functions such as shot count management has been installed to centrally manage all production data.

- Real-time grasp of operation status and progress status by receiving shot signals from molding machines

- Register work results on PC at any time to grasp the status of work-in-progress and completed inventory

- Immediate confirmation of production progress

- Immediate retrieval of history of each process when problems occur by centralized management (traceability)

Certificate holder

We promote the acquisition of national certification for injection molding technicians, and many of our employees have acquired such certification. Our technicians are in charge of setting injection molding machine conditions and managing injection molding machines and peripheral equipment to maintain high quality and ensure stable quality.

ISO 9001 and ISO 14001 certified

Quality Policy

To satisfy our customers, we continuously improve the quality of development, technology and services.le.

Conduct Guidelines

- Set challenging goals to realize Quality Policy.

- Share awareness of the quality issues and carry out Root Cause Analysis.

- Make continuous improvement by Plan Do Check Action cycle.

Overseas Quality Assurance System

IATF16949 is a quality management system added to ISO9001, and is an international standard that certifies that requirements specific to the automotive industry have also been met. Two of our four overseas plants,Shenzhen Factory and Philippine Factory, produce products that conform to the standard, ensuring that we always deliver products of consistent quality.

Shenzhen (China)

Qingdao (China)

Philippine

Vietnam

Main Equipment in Quality Control

X-Ray Elements Tester

- Measurement of RoHS prohibited substances

- Qualitative and quantitative analysis of materials and components of metal parts

Mitsutoyo Surface Roughness Measuring Instrument SJ-400

- Measurement range: X-axis (mm) 50

- Measurement range: Z1-axis surface roughness (μm): 800

Tooth lead, tooth profile and pitch measuring machine

- Capable of measuring tooth profile, tooth lead, and pitch error

- Compliant with new gear accuracy standard JIS B1702-1

Nikon Image Measuring Machine NEXIV VMR-3020

- 2.5D

- Measurement range: 300mm*200mm

- Gear shape evaluation is possible

- Max magnification: 280x