High precision gears and precision molding

Gear technology to meet various needs

With our know-how accumulated over the years, we listen to various customer needs such as sound, durability, accuracy, and strength, and propose the most suitable shapes and materials. We have measurement equipment that can evaluate the finish and accuracy of gears, and we can comply with JGMA and JIS. We identify and correct problem areas based on measurement results, and work to pursue accuracy. We can also provide machined gears for small quantities such as prototypes.

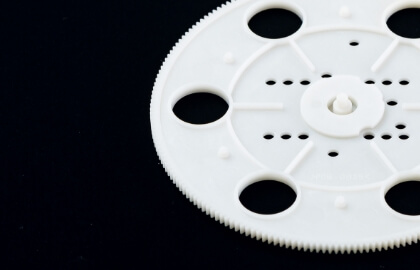

High precision gears

-

Spur gear

Raw material: POM Module: M0.8

This is the most widely used gear for power transmission, and can be used for JGMA0-class high-precision gears.

-

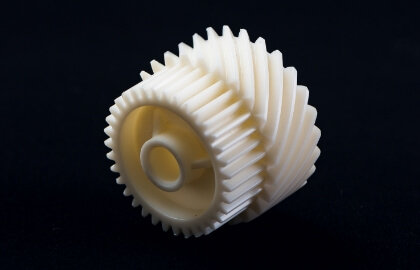

Helical gear

Raw material: POM Module: M1.0

Because it is helical, it is a gear with a good meshing rate and quietness.

-

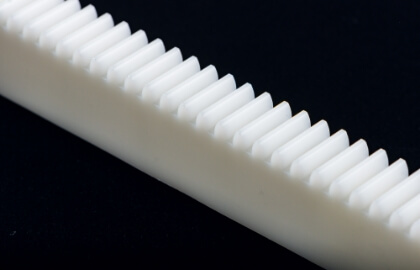

Rack Gear

Raw material: POM Module: M1.5

This gear can switch between rotational and linear motion.

-

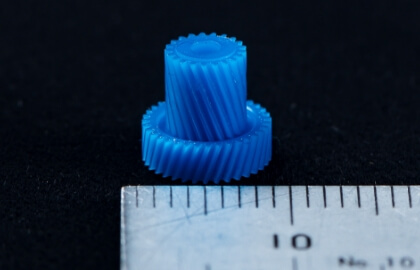

Small Module Gears

Raw material: POM Module: M0.2

We can also produce ultra-small gears for the lightening and downsizing of various precision equipment. We can produce gears from module M0.2.

-

Large Module Gears

Raw material: POM Module: M2.0

Large-module gears are strength-oriented, but precision is also required, so we propose rib shapes and other suggestions. We can produce up to module M2.25.

-

Worm Gears

Raw material: POM Module: M0.7

A large reduction ratio can be obtained with a single step, and these gears are used for high-torque power transmission.

-

Bevel Gears

Raw material: POM Module: M0.8

Spiral bevel gears are suitable for heavy loads and high rotational speeds, and their smooth rotation provides excellent noise and vibration performance.

-

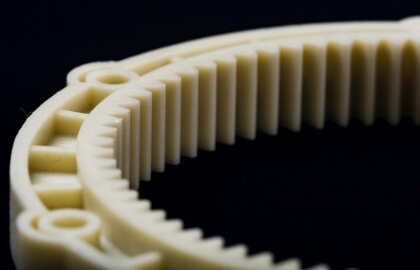

Internal Gear

Raw material: POM Module: M1.0

This gear has teeth arranged inside a cylinder. The mating gear that meshes with the internal gear is called a pinion. They are used in gearing devices such as planetary gears with high reduction ratios and gear type shaft couplings.

-

Large size gear

Raw material: POM Module: M0.65

Helical gears with outer diameter up to Φ120 in can be manufactured, and JGMA0-class high-precision gears such as OA output gears can also be handled.

-

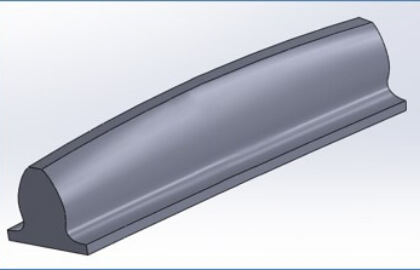

Crowning gear

Raw material: POM Module: M2.0

This gear is effective in meshing efficiency by providing a bulge toward the center of the tooth trace. Excellent quietness and low vibration.

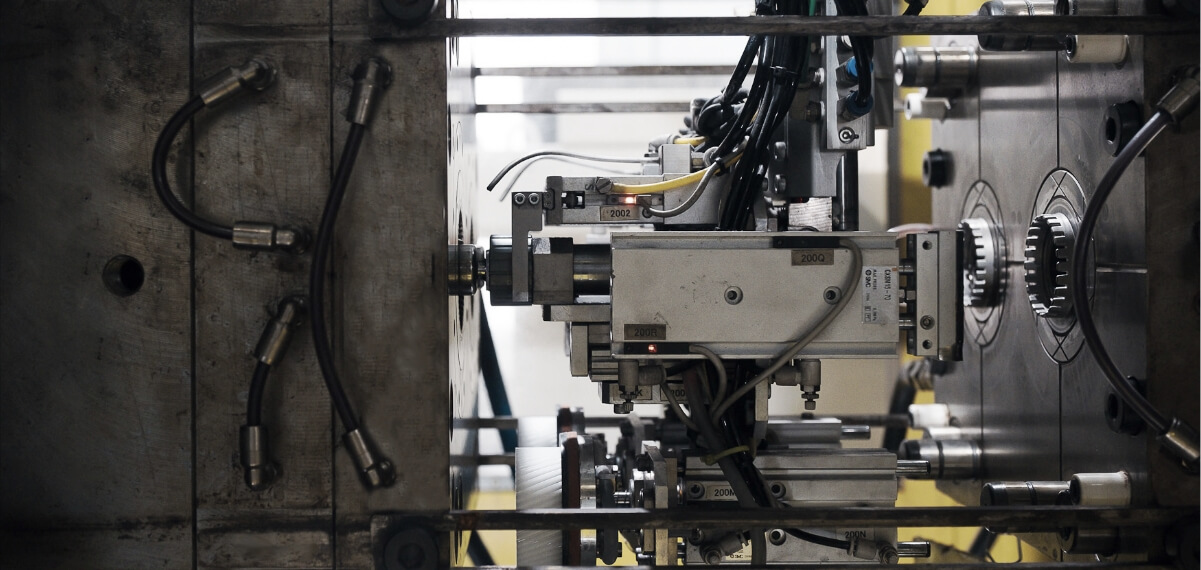

Precision Molding Technology

We can meet high-precision requirements by proposing optimal gate positions and shapes, and by using our molding and die technologies. We can also handle molded products of various shapes and raw materials by utilizing the know-how acquired through our high-precision gears. In the event of molding defects or mold problems, our skilled molding technicians will thoroughly investigate the cause and solve the problem. *Please contact us for details, as the products handled differ at each location.

Molding Technology

- *Pursuit of micron-level precision

- *Stable quality by setting the optimum molding conditions for each product by our injection technicians

- *Molding defects and problems are solved by cause analysis by highly experienced injection technicians

- *Regular maintenance of molds through shot count control

- *Supports up to Engineering plastics Super Engineering plastics

- *High-difficulty products such as thick, thin, and long products are also realized through know-how and proposals

Precision Molding Examples

-

Insert Molding

Raw material: POM

Resin-metal composite products. We propose the design of a retaining and turning stop to improve the joint strength.

-

Thick-wall molding

Raw material: POM

Due to the thick wall thickness of 6 mm, we propose an even wall thickness shape and set optimal molding conditions in consideration of the product application.

-

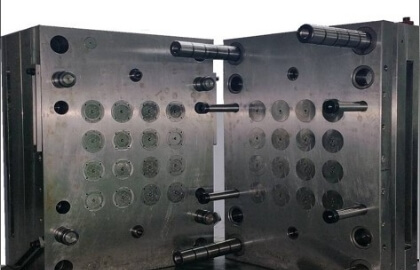

Multiple cavities

Raw material: POM

We can handle large-lot production. In order to prevent variations in product dimensions, mold design and conditions are set in consideration of simultaneous filling and balance.

-

Gear Unit

Raw material: POM

We can handle everything from individual molded products to lubrication, assembly, and noise inspection during operation.Multi-directional slide pulley.

-

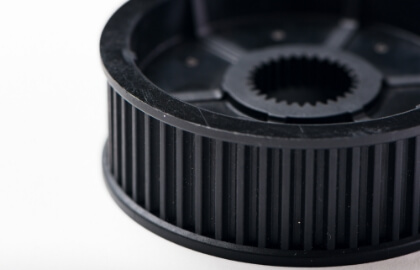

Multi-directional slide pulley

Raw material: PA66

Pulleys with double flanges used for automatic doors and other applications can be formed as a single piece by using a multi-directional slide for the mold.

-

Double Injection molding

Raw material: POM

Double Injection is a molding process that combines different resins or materials, specifically plastics and elastomers, into a single unit.

-

Multiple insert high-precision molding

Raw material: PPS

Insert molding using super engineering plastic. High precision with an inner diameter tolerance of 20 μm is achieved. We perform molding parts + magnet insert molding + ultrasonic welding.

-

High Temperature Material Gears

Raw material: PPS

Gears made of high-performance engineering plastics called “super engineering plastics” can be molded. Because of its crystalline nature and excellent heat, cold, and chemical resistance, it is widely use in a variety of fields.

What are Precision Resin Gears?

Resin gears are used in various fields such as office automation equipment, automobiles, bicycles, and industrial equipment, taking advantage of their light weight, low cost, and quiet operation. Typical types include spur gears, worm gears, rack gears, and bevel gears. They also vary depending on the application, such as helical gears for quietness of products and modular gears for downsizing and weight reduction of precision equipment. Raw materials range from “general-purpose plastics,” such as PP and ABS, to “engineering plastics (engineering plastics),” which combine sound, durability, precision, and strength.

Points to consider when OEM for mass production of precision polymer gears

Even with resin gears, the required performance varies depending on the environment and application. There is a wide range of plastics, from raw materials such as PP and ABS, which are called “general-purpose plastics,” to “engineering plastics” that combine sound, durability, precision, and strength. In addition, in the case of precision molding, analysis is also necessary to understand the state of warpage and deformation. There might be defect rate problem if just depending on mass production.

Points to consider when making a request

In the injection molding of precision resin gears, good molded products are realized under three conditions: mold technology, resin material, and production technology. In precision molding, analysis at the design stage is necessary to understand the state of warpage and deformation. If mass production is performed without such preliminary studies, defect problems will occur. It is also important to understand the characteristics of the resin material and select a material that meets the intended purpose. The shrinkage rate of resin varies depending on the type and product shape. Know-how is required to design the mold and set the molding conditions in anticipation of the shrinkage rate. Depending on the gear specifications, there may be cases where the current vendor is unable to handle the gear, so it is important to understand the OEM contractor’s track record and past cases of solutions in advance.

Examples of solutions in which OB Industries has been involved

- > Proposal of a design that enables fully automatic molding in contrast to a semi-automatic molding design

- > Proposal of technology to avoid optimal shape and wall thickness issues in order to convert metal to resin

- > Correction of tooth lead direction as a countermeasure for noise-signaling gears

- >(Crowning design)Propose optimal gate position by flow analysis to improve warpage

One-stop service from initial development to mold fabrication and mass production

As a “global precision molding manufacturer,” OB Kogyo has established a production system in ASEAN countries and can make proposals from prototype development. We promote VA and VE proposals, work on problem solving, and propose and support optimal shapes. We provide one-stop service up to mass production. We specialize in precision plastic molding and have over 50 years of business experience, problem-solving capabilities, and know-how. You can count on us for precision plastic gears!